Weaving traditional, technical and 3D textiles

Weaving traditional, technical and 3D textiles

The conversion/adjustment of machines

Different types of yarns

Alternative possibilities (non woven, knitting, printing,...)

Large network within the textile world

Possible after-treatments as well as the necessary contacts

Weaving techniques - See overview

3D Weaving develops always tailor-made for the customer. Based on an initial, exploratory discussion, we listen to the needs and/or wishes of the customer.

3D Weaving engages in the development of both new fabrics and those requested by the customer, examining whether it is technically possible to weave. If there is an alternative or a more cost-effective solution of equal quality available, other than a 3D fabric, this is communicated to the customer.

Here the weaving structure is

analyzed so we learn how the

fabric behaves.

All prototypes are woven on

industrial machines to identify

the knowledge and feasibility of

an industrial end product.

This involves analyzing the

necessary machine

modifications to begin industrial production.

©2025 Wide

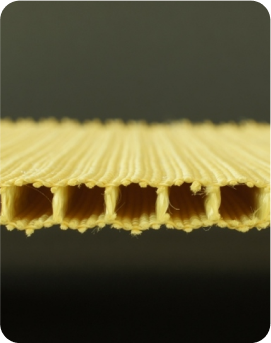

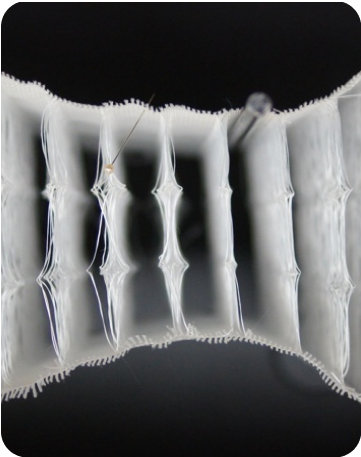

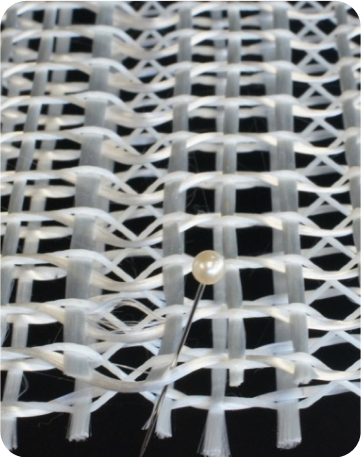

A distance fabric, also known as spacer or double-walled fabric, comprises interconnected woven layers using connection yarns in the third dimension. Various yarn types can be employed in the top and bottom layers, with customization options for fabric height and geometry of the connecting yarns. Specific yarns, such as anti-static yarns, can also be inserted at intervals.

Distance fabrics with constant height give two straight surfaces with a constant height in between.

A distance fabric can also be woven in a specific shape in length direction.

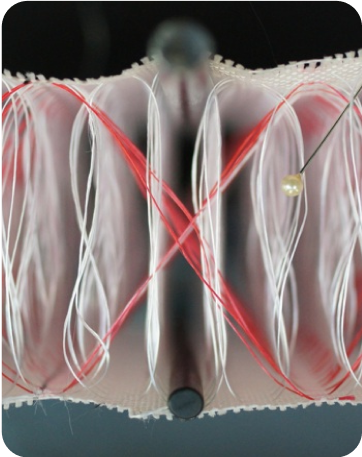

A stabilized distance fabric has connections yarns under an angle for a better resistance against shear.

A multilayer distance fabric consists of two distance fabrics woven above each other in one plece.

A distance fabric with a high open area

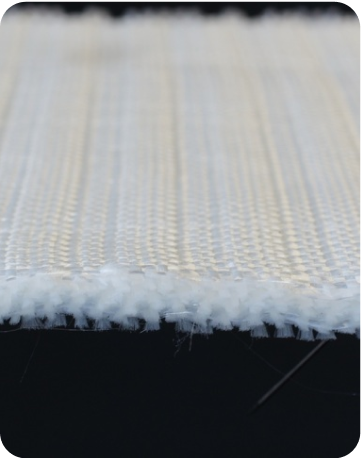

A multilayer fabric comprises stacked woven layers, limited to a maximum of 12 woven layers or 22 warp yarn layers and 23 weft yarn layers (unidirectional layers). Connection is achieved through third-dimensional connection yarns or interlocking, enhancing delamination resistance and reducing manual labor in layer stacking. Various yarn types can be utilized and mixed, either in different layers or within a single layer.

A multilayer fabric with non-crimp layers consists of unidirectional layers stacked on top of each other.

A multilayer fabric with woven layers consists of a number of woven layers stacked on top of each other and held together with connection yarns in the third dimension (Z-direction).

A multilayer fabric with interlocking is not kept together with an extra connection yarn system in the third dimension.

A combined multilayer fabric is a combination of different types of multilayer fabrics.

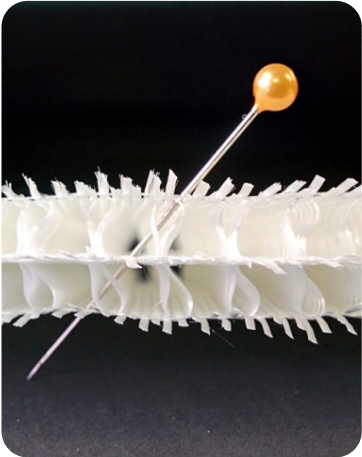

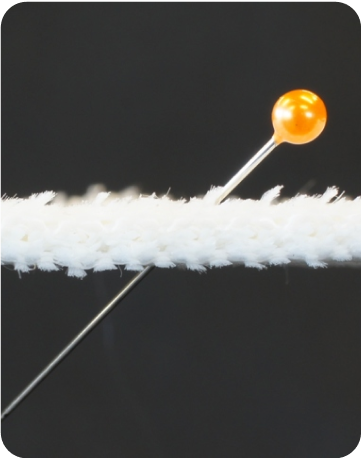

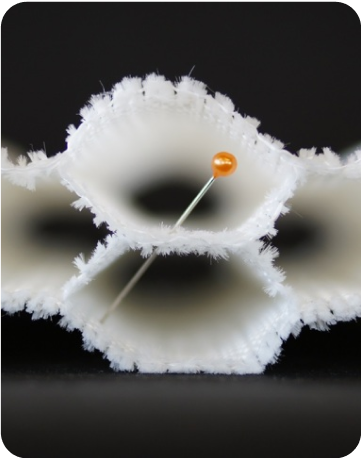

Tubular fabric, with customizable hollow spaces in a 3D woven structure, offers versatile surfaces for connections—profiled faces allow oblique or oblique-horizontal combinations, while flat surfaces can have vertical, oblique, or mixed connections. The fabric accommodates diverse yarn types, both across layers and within a single layer, enabling periodic variations for applications like utilities or reinforcement matrix and foam filling.

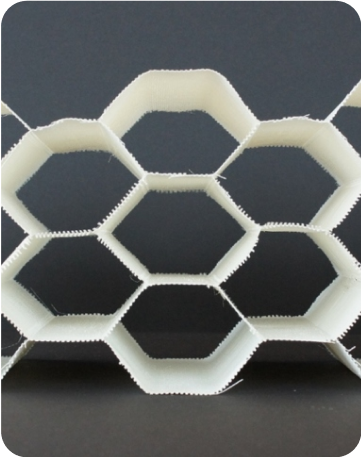

Tubular fabrics with profiled surfaces always have oblique woven connections (diamond shape), These connections can be in combination with horizontal connections as in for example a honeycomb structure.

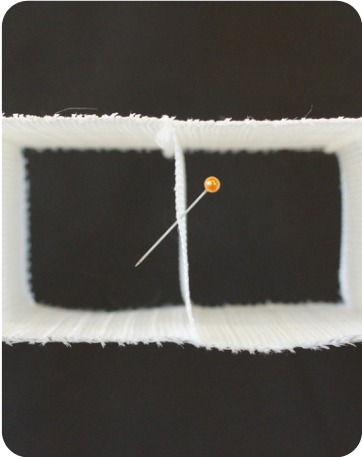

Tubular fabrics with flat faces and vertical woven connections have square or rectangular tubes in width direction.

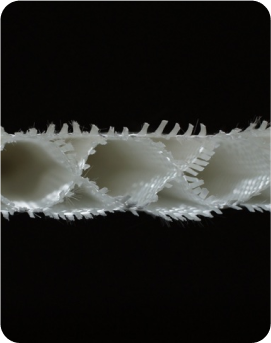

Tubular fabrics with flat faces and oblique connections have also woven connections under an angle that can be customized.

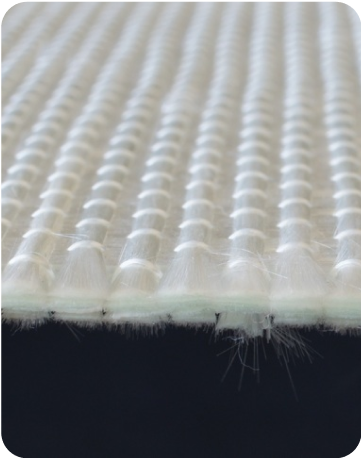

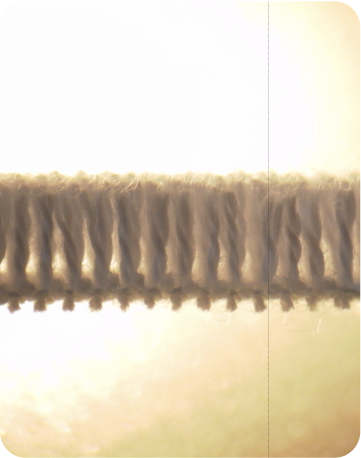

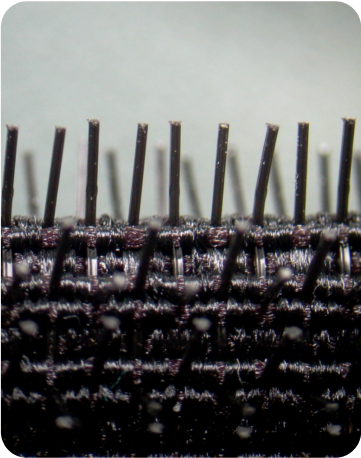

A pile fabric consists of a woven layer with perpendicular cut pile yarns as with normal velvet.

A pile fabric consists of a woven layer with perpendicular cut pile yarns as with normal velvet.

This category includes all woven fabrics that cannot be divided in five main categories. The woven fabrics can be a combination of different techniques, a jaquard woven fabric or a assymetrical woven fabric.

This complex fabric has pockets on one or two sides of the fabric.

This complex fabric is a combination of some or all of the above mentioned 3D woven fabrics.

With a jacquard loom all yarns can be individually controlled. Therefor a lot more irregular patterns are possible.